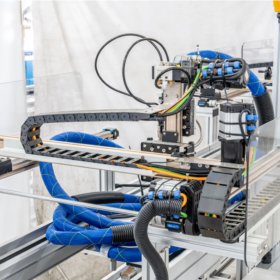

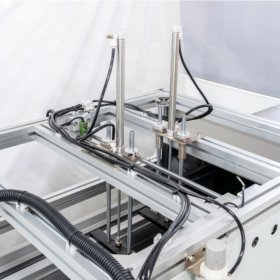

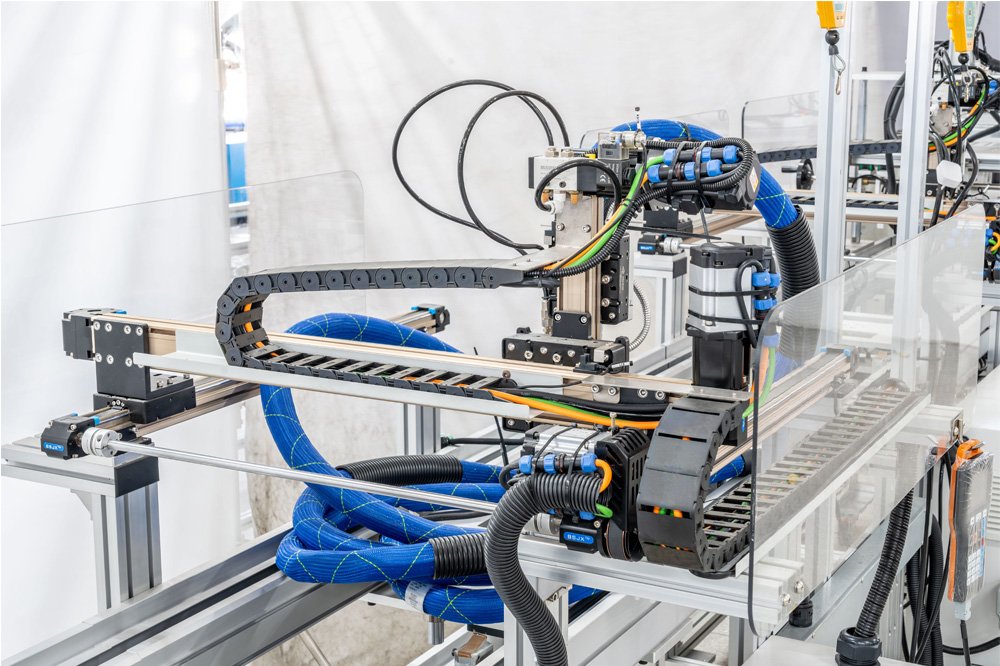

Introduction to Equipment Structure

Introduction to Each Institution

Introduction to Action Process:

1. The product is placed on the feeding conveyor belt;

2. Sensing the product – edge scraping – edge bonding;

3. The rough cutting and separation mechanism will cut and separate the products one by one after edge bonding;

4. The separated product flows onto the discharge conveyor belt.

Introduction to the Main Hardware Brands of the Equipment

1. Servo motor: Hechuan

2. PLC: Delta/Xinjie/Hechuan

3. Electrical accessories: buttons/Yijia; Relay/Omron; Contactor/Chint Schneider; Switching power supply/Mingwei

4. Touch screen: Weilun Tong

5. Sensor: Lugong/Luoshida

6. Synchronous belt module: Dongguan Baishan

HC-Air cabin filter supplier

HC-Air cabin filter supplier