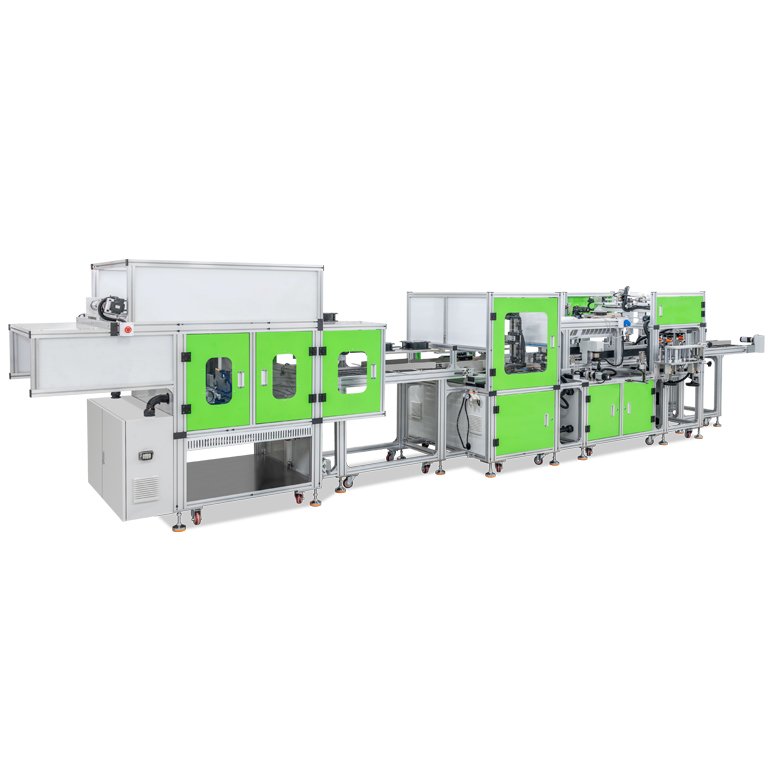

Equipment Parameter Introduction

- 1. The equipment is suitable for product range: length: 150~400mm; width: 150~400 mm; Height: 10-50mm

- 2. Scraping height: 10~50mm

- 3. Voltage: 220V; Air pressure: 0.6Mpa; Power: 14KW; Weight: 600KG

- 4. Efficiency: 7S (standard product 300×300)

- 5. Equipment size: length x width x height: 8600x2350x2000mm

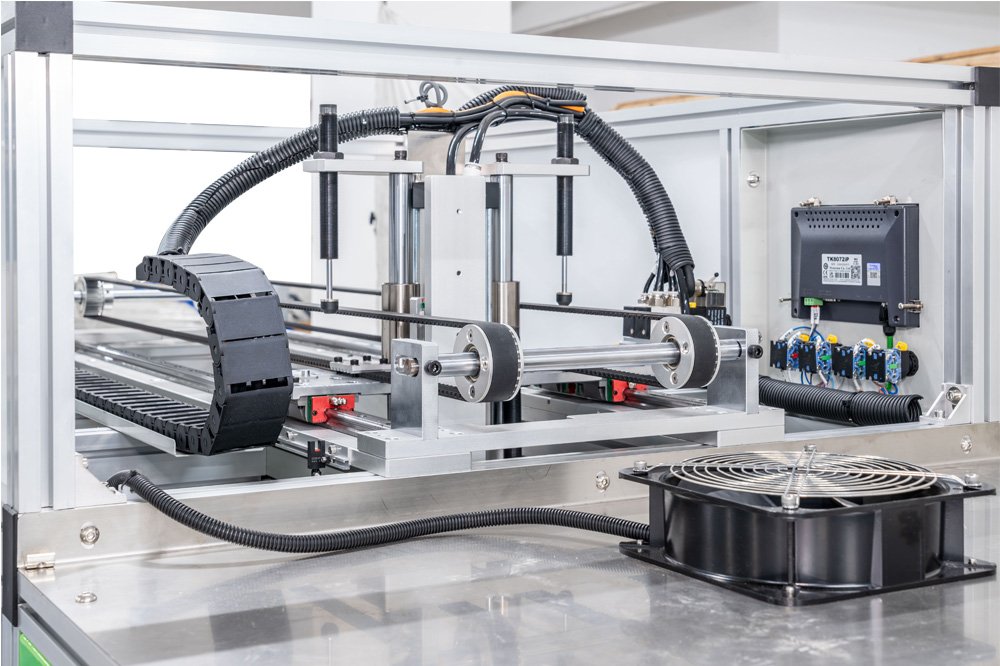

Action Flow Introduction:

1. The products are placed on the feed conveyor belt.

2. Sensing the product – scraping the edge strip – pasting the edge.

3. The inserting mechanism is inserted into the product and moves in the opposite direction

of the edge bonding so that the front and rear pages of the product are firmly attached to the edge strip.

4. The rough shearing and separation mechanism cuts and separates the products one by one after the edge is attached.

5. The fine- cutting mechanism performs fine-cutting on the product.

6. The finished product flows out from the discharging conveyor belt.

HC-Air cabin filter supplier

HC-Air cabin filter supplier