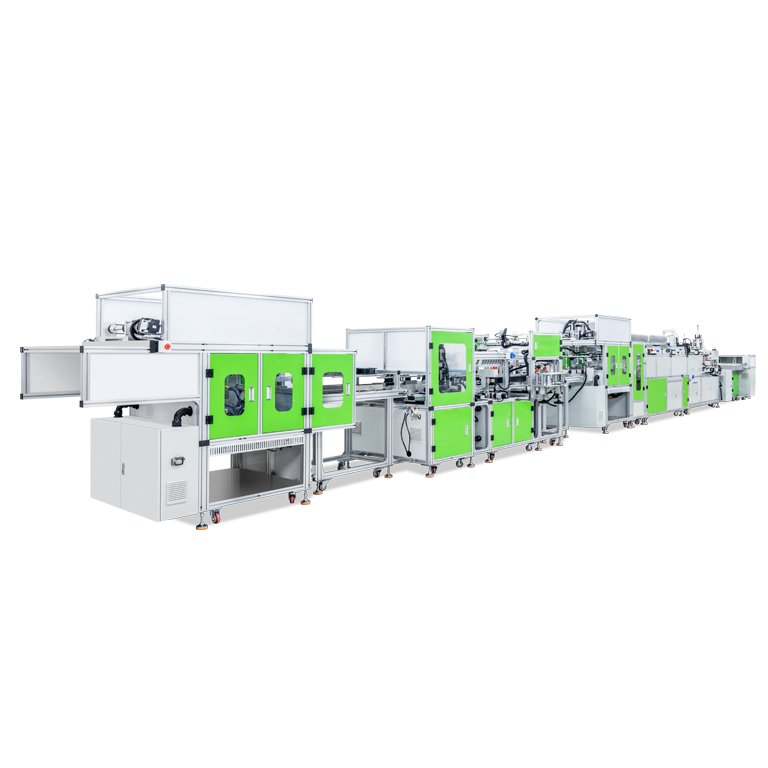

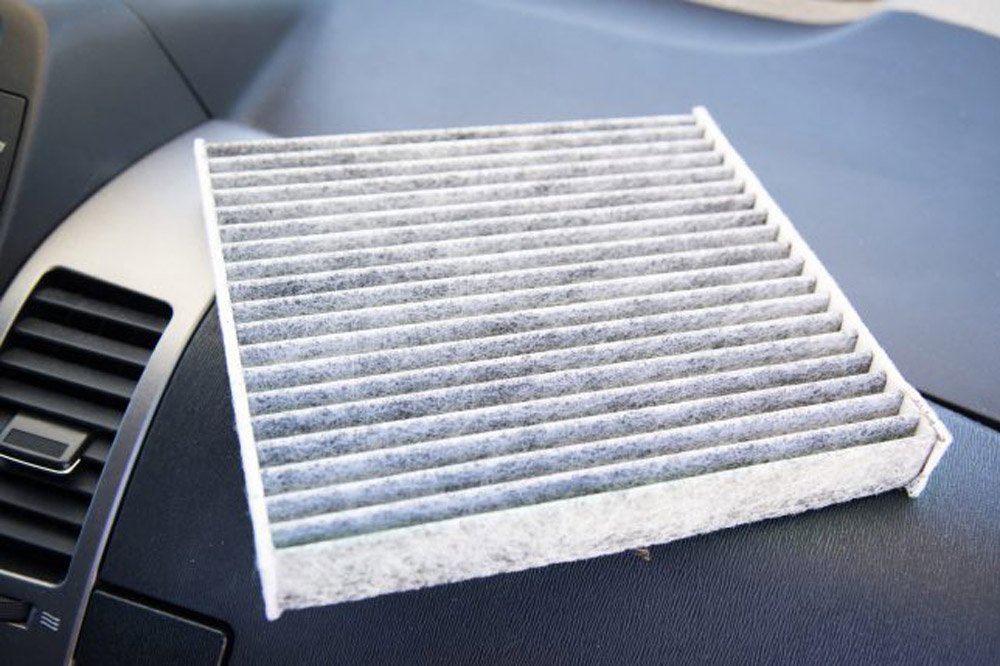

Automobile Air Conditioning Filter Paste Four-Side Production Line

Specification

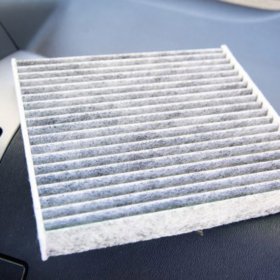

- 1. Product ranges: length: 150~400mm; width: 150~350mm

- 2. Scraping width: 12~50mm

- 3. Voltage: 220V/380V; air pressure: 0.6Mpa; power: 30KW; Weight: 1200KG

- 4. Action time of a single group of equipment: ≤7S

- 5. Eequipment footprint size: (L*W*H): 19000x3000x2000mm

- 6. Number of equipment operators: mold feeding (manual filter element discharge) ≥1

- 7. Number of circulating molds: ≥18

- 8. The equipment replacement time should be 0.5 hours

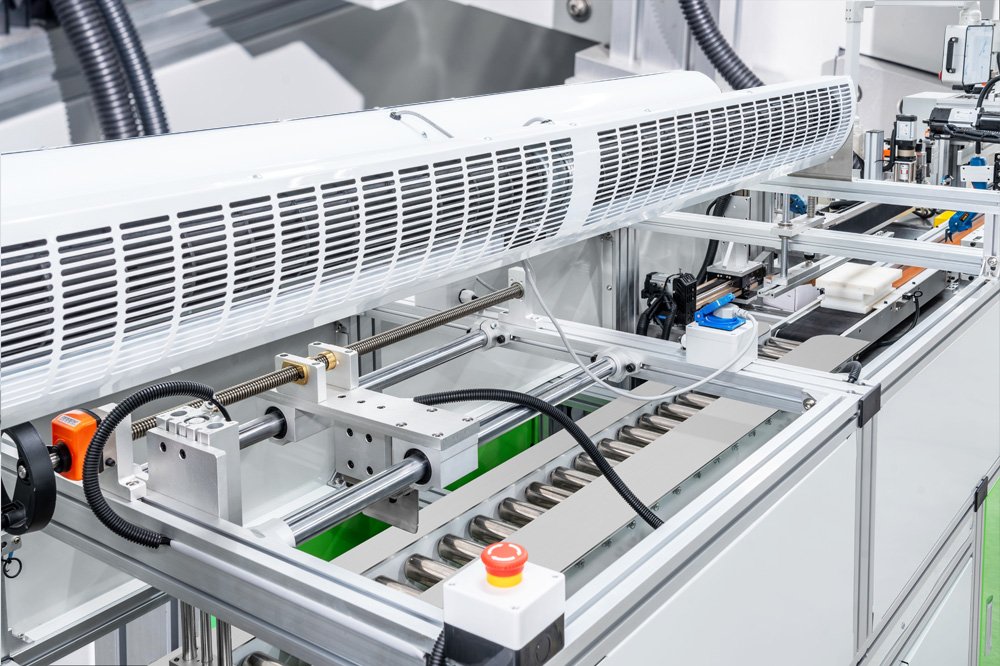

Introduction of Each Organization

Process Flow:

1. Operator loads products onto the shaping mold one by one.

2. Place filter onto conveyor line, automatic correction and edge attachment.

3. Automated trimming after edge attachment.

4. Separated products enter automatic demolding mechanism.

5. Molds return to work platform via elevator convey.

6. Automated precision trimming after demolding.

7. Ready for collection on conveyor line.

Equipment Size Description

The equipment consists of eight parts, which can be detachable, each of which does not exceed 2.5 meters in length.

Eequipment structure introduction: Short side

Introduction of Each Organization

Process Flow:

1. Products placed on feed conveyor belt.

2. Sensing priduct — edge scraping — edge banding.

3. The insert mechanism is inserted into the product and moves in the opposite direction of the welt, so that the front and back pages of the product are firmly attached to the edge strip.

4. The coarse trimming separation mechanism will cut the products one by one and separate them.

5. The precision mechanism performs fine cutting on the product.

6. Finished products exit via output conveyor belt.

HC-Air cabin filter supplier

HC-Air cabin filter supplier