Action Flow:

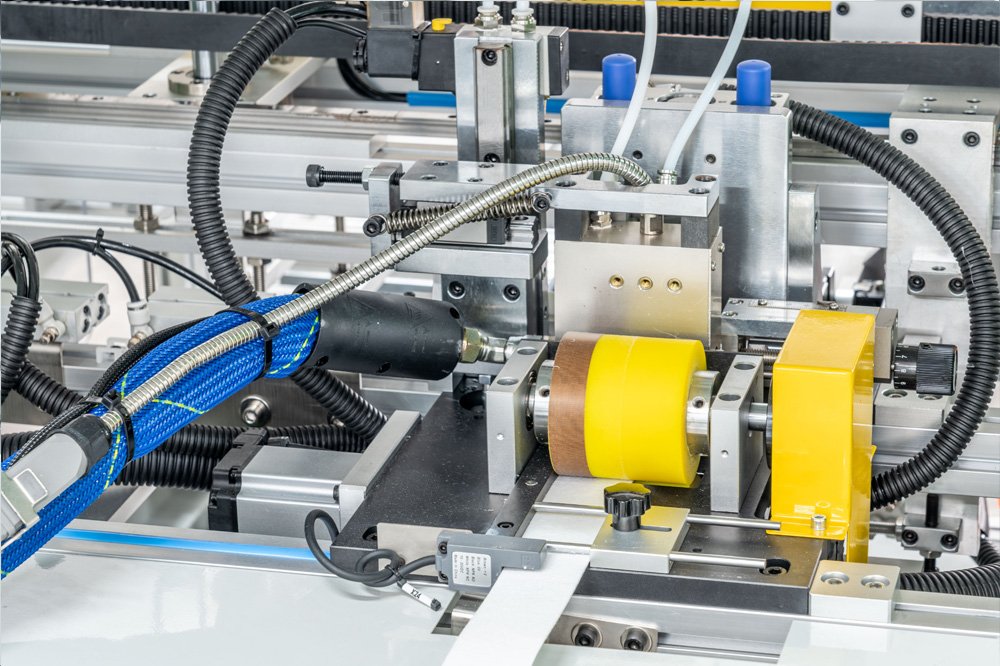

1. The operator places the product on the jig of the fully automatic hemming machine, and the equipment automatically hems the product;

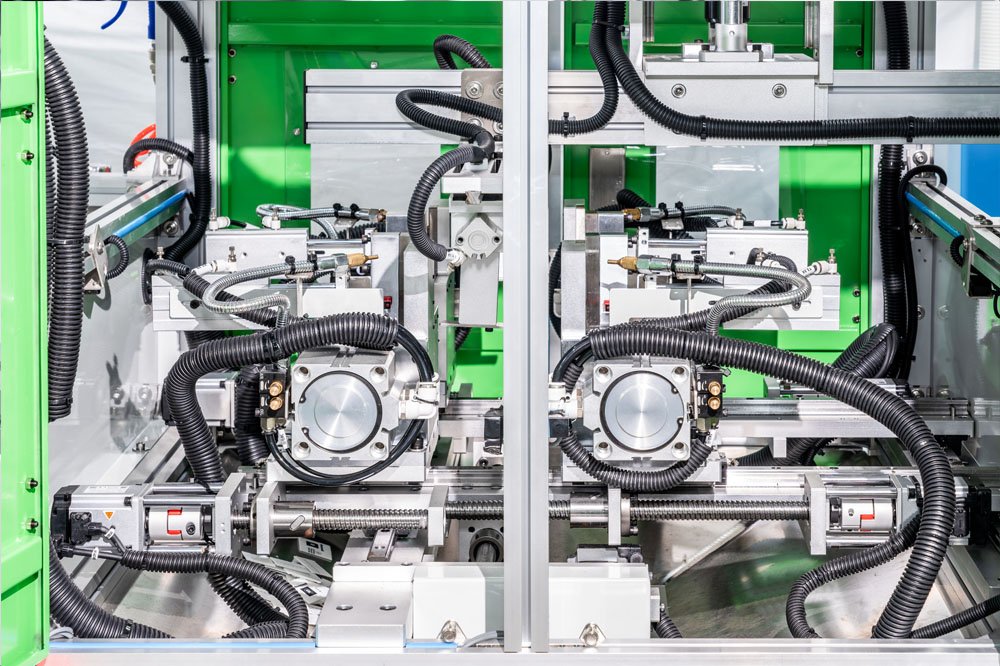

2. The hemmed product is grabbed by the robot of the fine shearing machine and taken to the designated position for fine shearing;

3. After fine shearing, the robot places the product on the discharging conveyor belt for discharging.

Equipment Parameter Introduction

- 1. The equipment is suitable for product range: length: 100-400mm; width: 100-300mm; height: 10-60mm.

- 2. Scraping height: 10-60mm.

- 3. Voltage: 220V/380V; Air pressure: 0.6Mpa; Power: 10KW; Weight: 1200KG.

- 4. Efficiency: 14S-15S/piece.

- 5. Equipment footprint: length x width x height: 6500x3000x2000mm.

- 6. Whole line product conversion time: <40 minutes (1 person).

- 7. The equipment has two modes: the hemming machine system and the fine shearing machine system can be used in sections, switchable.

- 8. The coil tray can be used with a width of 10~100 and a coil diameter of 800mm.

HC-Air cabin filter supplier

HC-Air cabin filter supplier