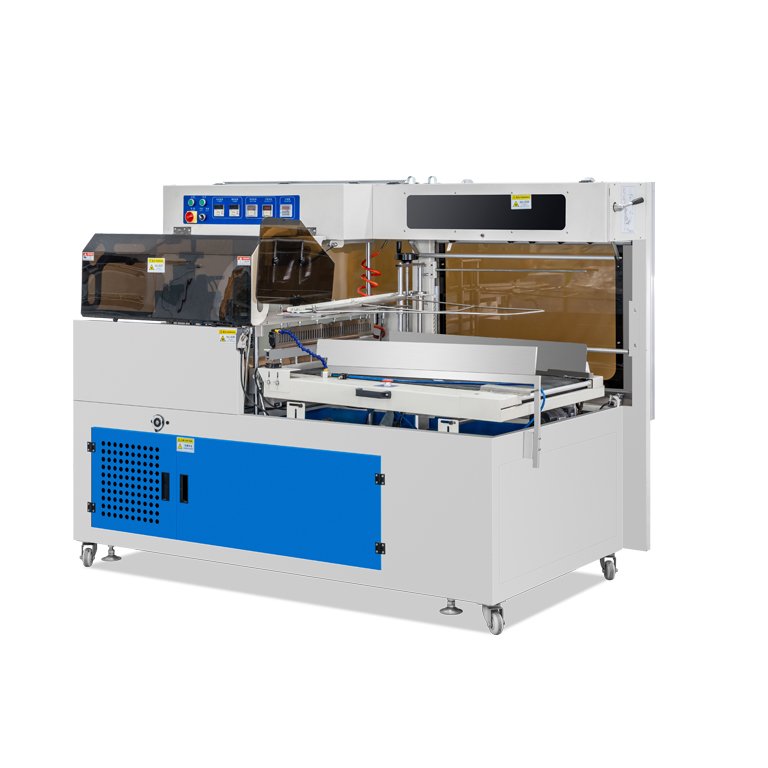

A shrink film packaging machine is a packaging powerhouse that applies heat to shrink a plastic film around a product. This process, often automated but also available in manual and semi-automatic variants, transforms packaging into a tightly sealed, protective cocoon. The magic happens when the wrapped product journeys through a heat tunnel or oven, causing the plastic to shrink, conforming snugly to the item.

| Filter size scope | 500*350*80 mm Min. 150*150*10mm |

| Equipment production beat | 5-20s/ piece (including the operator’s discharge time) |

| Voltage | 380V |

| Power | 12KW |

| Air pressure | 0.6-0.8Mpa |

| Operation mode | PLC control system |

Fournisseur de filtres d’habitacle HC-Air

Fournisseur de filtres d’habitacle HC-Air